It may not be the most obvious of substrates, but corrugated board lends itself to both screen and digital printing alike.

A rigid yet lightweight material it has many uses, not all of them packaging related.

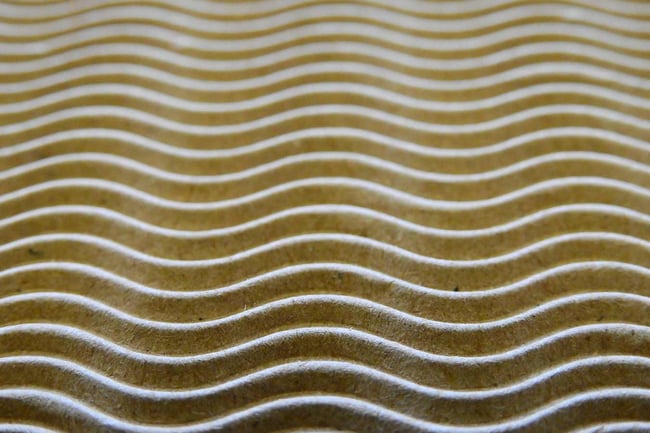

Corrugated board is made up of two paper faced liners which surround a corrugated structure often referred to as a ‘brown flute’. The flute itself comes in various forms dictating length and is classified with letters including B,E, E/B and many more besides.

Printing onto this surface was, for the longest time, a challenge. The spongy texture would often crumble under any significant pressure and led to many printers simply abandoning the idea.

As a result, corrugated board became synonymous with dull packaging, devoid of much in the way of design or inspiration.

Times though have changed, and technological advancements mean the likes of Evans Graphics can now not only print onto the material but apply finishing touches that greatly enhance it.

Benefits and Applications

So why would you adopt this as your substrate of choice?

Corrugated board has plenty going for it. Available in a range of thicknesses, it prints and converts well, whilst being versatile and eco-friendly.

A relatively cheap material to print onto, it won’t break the bank. Nor will it falter when exposed to the elements if you opt for waterproof coatings designed to guard against that.

Lightweight, it’s easily transportable and just as easily drilled should you wish to fix your product to a surface.

Yes, corrugated board is both practical and printable and much sought-after when it comes to packaging for custom materials/products.

Aside from that one, rather obvious function, you may utilise it for the following:

- Freestanding Displays

- Cartons and Boxes (shipping, clothing, jewellery, bakery)

- Temporary promotional signage

- Floor protectors for paintings

- Gift packaging

- Children’s Toys

Printing

To realise any of the above you’ll need to apply your design through one of digital or screen-printing means.

The former is the simpler of the two when it comes to these particular products. It’s also decidedly quicker, given there is no requirement for printing plates or lamination processes.

Instead Evans Graphics use a combination of large format printers and UV inks to print directly onto the corrugated board, replicating a digital image exactly. This option also allows for double sided printing. Of the two, digital printing is better for short-runs.

But screen printing onto corrugated board brings its fair share of advantages too. By adopting stencils and forcing ink through them with a squeegee you allow for a greater build-up of ink. This is far better for any designs that contain solid block colours. Replicating these is easier with screen printing than relying on CMYK detail. Complex designs, it could be argued, are more attainable this way.

They’re also made possible with the help of finishing technology, which can turn flat board into 3D designs and all manner of imaginative shapes.

The laser guided cutting tables deployed by our team enable our clients to realise square, circular and triangular displays among others. In fact, pretty much any shape is achievable, which is music to the ears of those planning marketing packaging they hope will differentiate their brand from competitors.

Finishing options extend beyond mere shaping meanwhile. The likes of double-sided adhesive can be applied for a sticker-like effect. Velcro hooks or loops do likewise, while others plump for magnetic tape that allows them to stick a fixture to a wall.

For promotional displays, plastic or metal struts can be attached to the back of the board, making them freestanding and more impactful.

Finally gloss varnish may be applied to offer further protection.

In short, corrugated board is capable of far more than you might imagine. A combination of good design and good print can unlock its potential.

Click here to learn more about printing onto corrugated board...