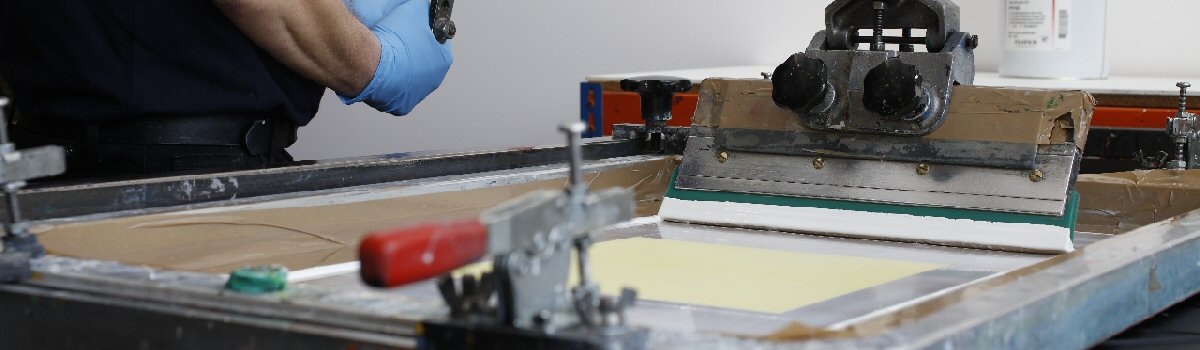

Typically, screen printing is great for applications such as fascia’s, metal panels, vinyl stickers and polypropylene wallets and binders. It's also the best printing technique for designs that require a metallic finish.

Of course, there are pros and cons to every printing method, and the route you chose should be informed by what kind of project you have and what kind of design you are looking to achieve. If you want to know more about screen printing and whether it is right for your project then keep reading!

Screen printing it often misconstrued as being a bit ‘old school’, particularly when compared to newer and more popular methods like digital printing - the pros and cons of which can be read here.

How screen printing works may sound dated (the rubber squeegee is certainly a throwback) but it remains superior in a number of ways and a better choice for certain projects. It should never be dismissed out of hand.

Pros

Flexible In Terms of Print Material

Screen printing really is unrivalled when it comes to flexibility. You can print onto almost anything as a surface providing it's flat. This includes plastic, metal and wood to name just a few, meaning the design you create could be turned into signs, office stationary and much much more!

It also remains the go-to for fabric printing and anyone looking to create custom t-shirts. Screen printing is really flexible when it comes to product shape, simplifying prints intended for more obscure shaped products.

What to know more about what can be produced this way? Uncover screen printing applications.

Perfect for Simple Design

If you are looking to print a simple design or text then screen printing is the ideal method to choose. Generally speaking, screen printing is best for artwork that has solid colour and isn’t photography based making it ideal for printing logos, company names or graphics. Gradients can also be achieved with screen printing and will leave you with a crisp, sharp design.

Ideal for High Print Volume

One of the beauties of screen printing is that the more products you have to print, the lower cost you will face. Despite having a complex set up process, screen printing usually only needs to be set up once so you can prepare you designs and go! This is great if you have a high volume of products to brand as your costs won’t increase which contrasts to other methods like digital printing which are often sold at a flat rate.

Durability

Screen printed designs are typically much more durable than the likes of heat press or digital designs which is due to the technique laying down thick layers of ink which are absorbed by the material, leading to enhanced durability, especially when a product will be under direct contact with sunlight, often causing them to fade which is a common characteristic of digital printing for example.

Cons

Requires High Print Volume

While screen printing is ideal for products in high volumes, it isn’t as cost effective if you have only a few items to print. The setup time is complex and involved so printing in low quantities won’t necessarily provide you with a cost effective result. Some printers will even limit the quantity they will print in so it’s worth checking this with your print provider first!

Set Up Time

As discussed, the set up for screen printing is much more complicated than the likes of digital or heat press printing, it also takes much longer so typically has a slightly slower turnaround time than other print methods. The common set up for screen printing involves imaging your design onto a fine-mesh screen which is then transferred onto the print material with ink. However for each colour/shape within your design a new screen is required. When adopting this method it's important to stock up on screen printing supplies.

Limited Colours

The process of screen printing doesn’t lend itself well if you are looking to achieve a design with a wide range of colours or a photography-based design. Spot colours can be mixed with a good degree of accuracy however, achieving specific gradients/shades is difficult.

Many print providers will offer a finite number of colours to choose from so it is worth asking your print provider for advice on your design and how it might be affected in terms of colour. Here at Evans Graphics for example, we have a team of experienced graphic designers who are on hand to help you with your design from start to finish.

Undecided on which method is best suited to your design? Read our Digital Printing Versus Screen Printing blog for a more detailed comparison.

We’ve Got You Covered

Whether you are looking for monochrome posters or technicoloured stickers, Evans Graphics can work with you to meet your specific screen printing requirements. Unlike many other print providers, our screen printing process is incredibly flexible and can be adapted to ensure you get the finish you are looking for. We also have an in-house professional design team who are on hand to offer design and printing advice where needed. All of this and more is explained in our screen printing FAQs.